Unlock Value with Smart Choices: Affordable Laser Welding Machines

Laser welding machines are essential for precision and strength in joining metals and thermoplastics across a variety of sectors. Discover how to select a cost-effective laser welding machine that meets your needs with our comprehensive guide.

Understanding Laser Welding Machines

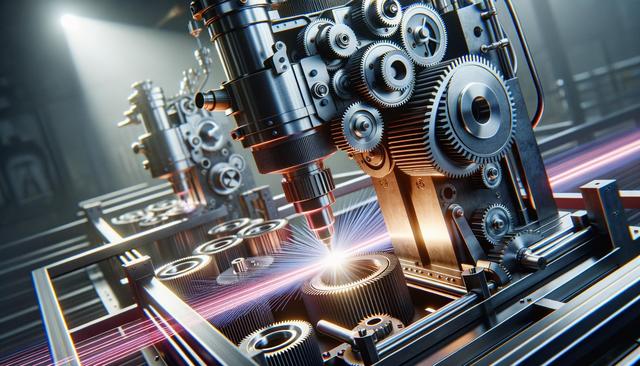

Laser welding machines have transformed the landscape of manufacturing and metalworking. These machines utilize focused laser beams to join materials, offering precise and clean welds that are especially beneficial for intricate designs and delicate materials. The technology is widely used in automotive, aerospace, electronics, and various other industries where precision is paramount. As industries continue to demand higher quality and more efficient production processes, laser welding machines have become indispensable.

Key Considerations in Selecting a Machine

When selecting a laser welding machine, it’s crucial to consider your specific needs and applications. Start by evaluating the materials you work with, as different machines are designed to handle specific materials like steel, aluminum, and thermoplastics. Consider the thickness and size of the materials; some machines are more suited for fine, detailed work, while others handle larger, thicker pieces.

Key factors to consider include:

- Power Output: Ensure the machine can deliver the power needed for your materials.

- Beam Quality: High-quality beams result in finer welds.

- Ease of Use: User-friendly interfaces and automated features can enhance productivity.

- Maintenance Requirements: Opt for machines that are easy to maintain and have accessible support.

Cost-Effectiveness and Smart Investment

Investing in a laser welding machine is a significant decision, so finding a cost-effective solution that doesn’t compromise on quality is crucial. Look for machines that offer flexibility for various applications, as this can maximize your return on investment. It’s also wise to consider the total cost of ownership, which includes not only the purchase price but also maintenance, consumables, and potential downtime costs.

Consider purchasing machines from trusted manufacturers known for quality and durability, as these often provide better long-term value. Additionally, machines with energy-efficient designs can help reduce operating costs.

Technological Advancements and Features

Modern laser welding machines are equipped with a range of advanced features enhancing their functionality. Many machines now incorporate automated systems, allowing for seamless operation and reduced manual intervention. Real-time monitoring and control systems ensure precision and consistency in weld quality, which is particularly useful in high-stakes industries.

Consider machines with programmable settings for different materials and tasks, as this flexibility can significantly improve efficiency and output quality. Some machines also offer connectivity features for integration with existing manufacturing systems, streamlining operations.

Conclusion: Making the Right Choice

Choosing the right laser welding machine requires careful consideration of your specific needs, industry standards, and budget constraints. By focusing on machines that offer high power output, exceptional beam quality, and ease of use, you can unlock significant value and enhance your manufacturing capabilities. Whether you’re a small workshop or a large industrial operation, investing in the right laser welding technology can position you competitively in the market, offering precise, reliable, and efficient welding solutions.